Humbug! How the Christmas confection was made

Edmonton candy-maker came out of retirement to produce treats the old-fashioned way in 1982

Candy-making isn't something just anyone can do, especially in mass quantities.

But Bill McCreedy could — and he did, even coming out of retirement to pitch in during the busy lead-up to the holiday season.

"If your mouth-watering job is making candy for Christmas, everyone's happy," said George McLean, host of CBC's The National, on Nov. 27, 1981.

McCreedy's specialty was humbugs.

It started with a copper kettle

McCreedy had begun working at Edmonton's Pavey Candy Co. at 16, according to a 2016 post on a website devoted to aspects of the city's heritage.

"Another batch of humbugs cooking in the heart of candyland," said reporter Warren Michaels, taking viewers on a tour of McCreedy's process.

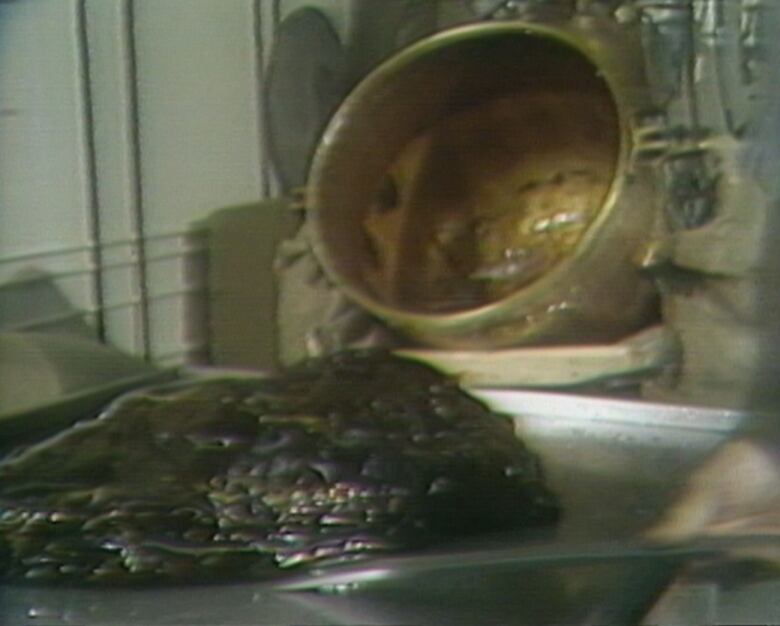

It started with a mixture boiling furiously in a giant copper kettle over tall flames.

'A big blob'

Then McCreedy and a strong co-worker tipped the contents onto a table, where McCreedy got to work with a blade, manipulating the deep brown mass into shape.

"It starts out as a big blob, but then he works the molten candy like bread," said Michaels.

McCreedy had come to Canada from Ireland shortly before beginning his job at Pavey's, according to the article by writer Lawrence Herzog.

And humbugs were his favourite.

The white stripes came next

"It won't be long now before we see how he gets the lines in," said Michaels, as McCreedy was shown stretching a taffy-like mass of white candy over a rod designated for the purpose.

Then a long rope of the white candy was placed between two thicker lengths of the brown.

"The secret has to be experienced, really," said McCreedy. "As you go along over the years you're always learning something new."

Then the candy was pulled out into longer strips, cut into sections, and bundled together.

A 'giant humbug'

"Really, I guess you're an artist," said McCreedy's voiceover.

Then the "giant humbug" that resulted was ready.

"This equipment is unchanged from the day he first walked through the doors of Pavey's 54 years ago," said Michaels.

McCreedy preferred it that way, even if more modern equipment was available.

"[That] makes it easier to make candy, but he says [it] takes the romance out of it," added the reporter.

Some help for the final step

Finally, the humbug rope was fed into a spinning wheel that cut it into individual candies.

McCreedy's longtime colleague, Jean Burns, also came back into the Pavey's fold to lend a hand during the Christmas rush.

"From the kettle to this point it takes about 20 minutes, and a lifetime of experience to make good humbugs," said Michaels.